More efficient and sustainable

Tetrashield plays a role in enhancing the sustainability of vehicles and manufacturing facilities. Coatings formulated with Tetrashield contain fewer volatile organic compounds (VOCs) compared to other coatings, resulting in fewer potentially harmful substances being released into the environment. This aligns with emerging environmental regulations and allows formulators and manufacturers to meet these evolving standards.

Automotive manufacturers can also experience improved efficiency. By using Tetrashield in coatings, higher solid levels can be achieved, enabling faster coating of more cars with less paint. That cuts energy use in a key area; around half the energy used to build a car is consumed in the paint shop.

- Microscratch test

- Scratch resistance by microscratch test

- Surface comparison

- Weathering comparison: UVB-313, ASTM G154

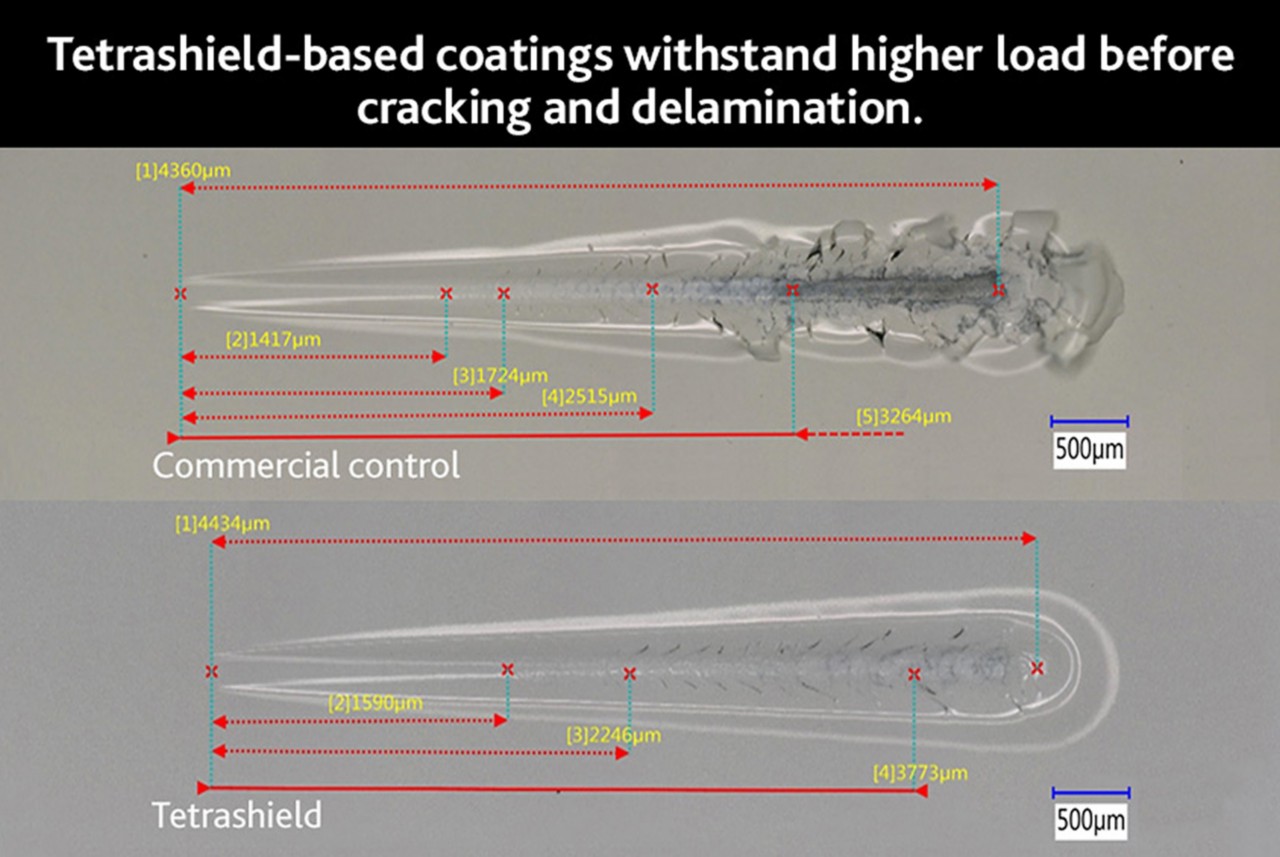

Microscratch test (AC1001 monocoat)

The Tetrashield-based monocoat demonstrates superior deep scratch resistance, making it better able to survive tree branches, keys and the rigors of daily life.

For this test, a monocoat was applied to each panel. To determine scratch resistance, each panel was subjected to a microscratch test using a progressive load up to 50 newtons across 5 mm of the panel. The test determines various damage points and coating failure. The commercial control cracked and delaminated. The Tetrashield-based monocoat withstood higher loads and did not delaminate.

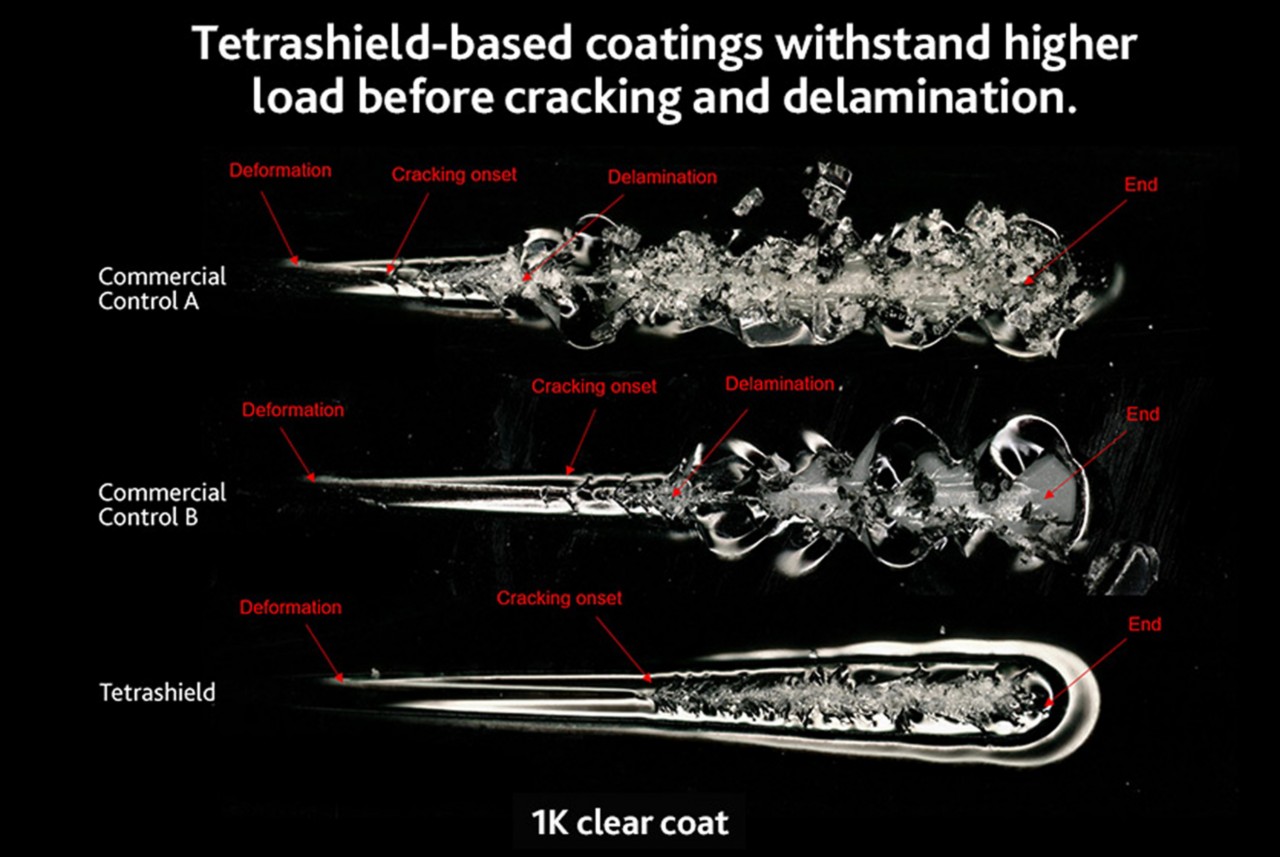

Scratch resistance by microscratch test (1K clear coat)

For this test, a 1K clear coat was applied to each panel. To determine scratch resistance, each panel was subjected to a microscratch test using 30 newtons of maximum load covering 5 mm of the panel. The test determines various damage points and coatings failure. The coating failed earliest on commercial control A. Commercial control B soon followed. However, the Tetrashield-based clear coat showed superior robustness and never delaminated.

The results demonstrate the exceptional durability of a Tetrashield-based coating, which allows vehicle exteriors to retain their appearance.

Under conditions that would leave deep scratches in current commercial automotive clear coats, Tetrashield-based coatings can remain intact.

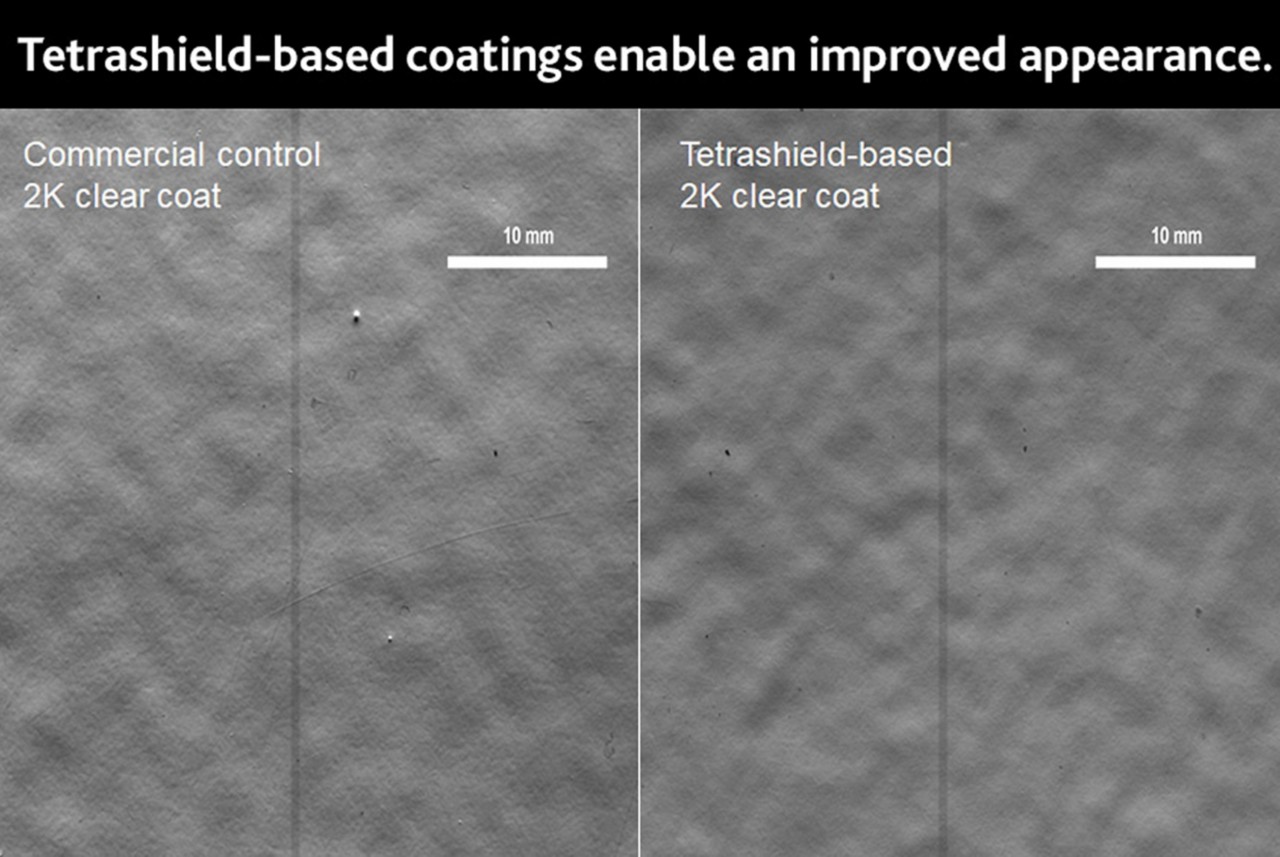

Surface comparison (2K clear coat)

These bell-sprayed panels have differences in microroughness and, therefore, also have differences in shortwave features such as Wa, Wb and distinctness of image (DOI). Images were captured using a line-scan camera. To help isolate longwave (bigger) and shortwave (smaller) features, the images were processed with fast Fourier transform (FFT) band-pass filters.

In comparing the two panels, stark differences were noted in the shortwave features. Software analysis revealed that the commercial control had approximately five times the number of features measuring between 0.3–1.0 mm compared to the Tetrashield-based coating. The number of longwave features was approximately equal between the two samples.

With a simple visual assessment of the two coatings, the difference in small features is also evident and has been quantified separately via optical profilometry, with surface roughness measurements confirming a smoother surface on the Tetrashield-based coating.

The difference in small features is a key factor that enables a smoother coating. As a result, an improved sharpness and brilliance of the Tetrashield-based clear coat is evident when looking at the car's surface.

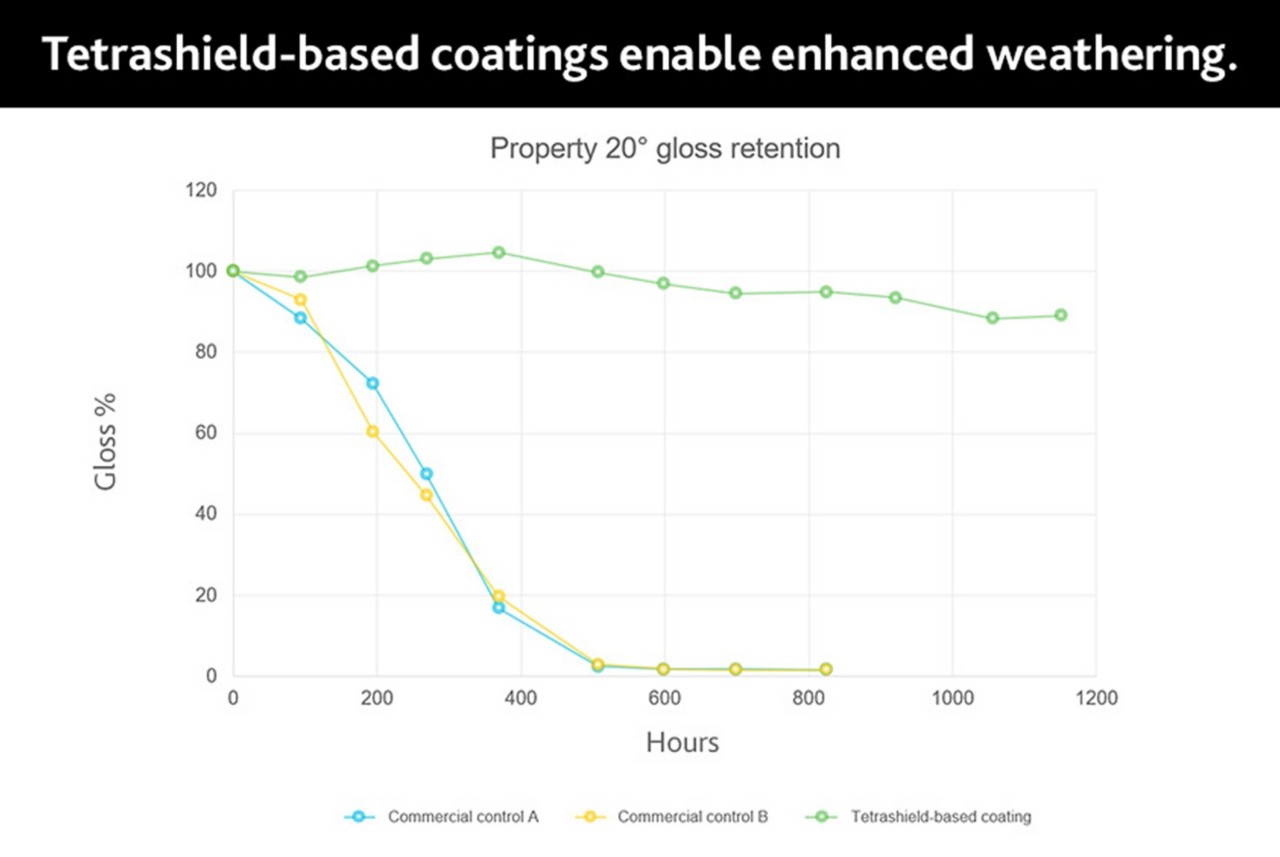

Weathering comparison chart: UVB-313, ASTM G154 (white AC1001 monocoat)

This test simulated the weathering effects that occur when materials are exposed to sunlight and moisture such as rain or dew in actual use. The weathering cycle consisted of four hours of light at 60ºC and four hours of darkness with condensation at 50ºC. Initial gloss was measured for all the samples, and gloss retention was monitored periodically.

The Tetrashield-based coating showed excellent gloss retention after 1,200 hours of exposure (more than 85%) with minimal deterioration in appearance, whereas commercial controls A and B degraded significantly to exhibit less than 20% gloss retention at just 400 hours of exposure. The Tetrashield-based coating demonstrated superior weathering characteristics; in a real-world environment, these characteristics enable vehicles to maintain their appearance even under various environmental factors.

Get protected

Tetrashield has options to meet many needs for automotive formulators as well as professionals in other industries. Use the link to find the right product for you.