Celebrating Skydrol’s 75th anniversary. See what else is set to take off.

Hydraulic fluids are the lifeblood of the normal airliner. Though they account for less than 0.1% of the fluid on that airliner, for anyone on board the benefits of Skydrol™ aviation hydraulic fluids can be felt a thousandfold. “When you’re in turbulence, that airplane is doing things constantly — wing flaps, flight controls. All of that power is supplied via Skydrol,” said Eastman Research Chemist Brad Payne. “Safety to the public, to the flying public, is really what it boils down to. The people in this business are passionate about that.”

Providing a lift

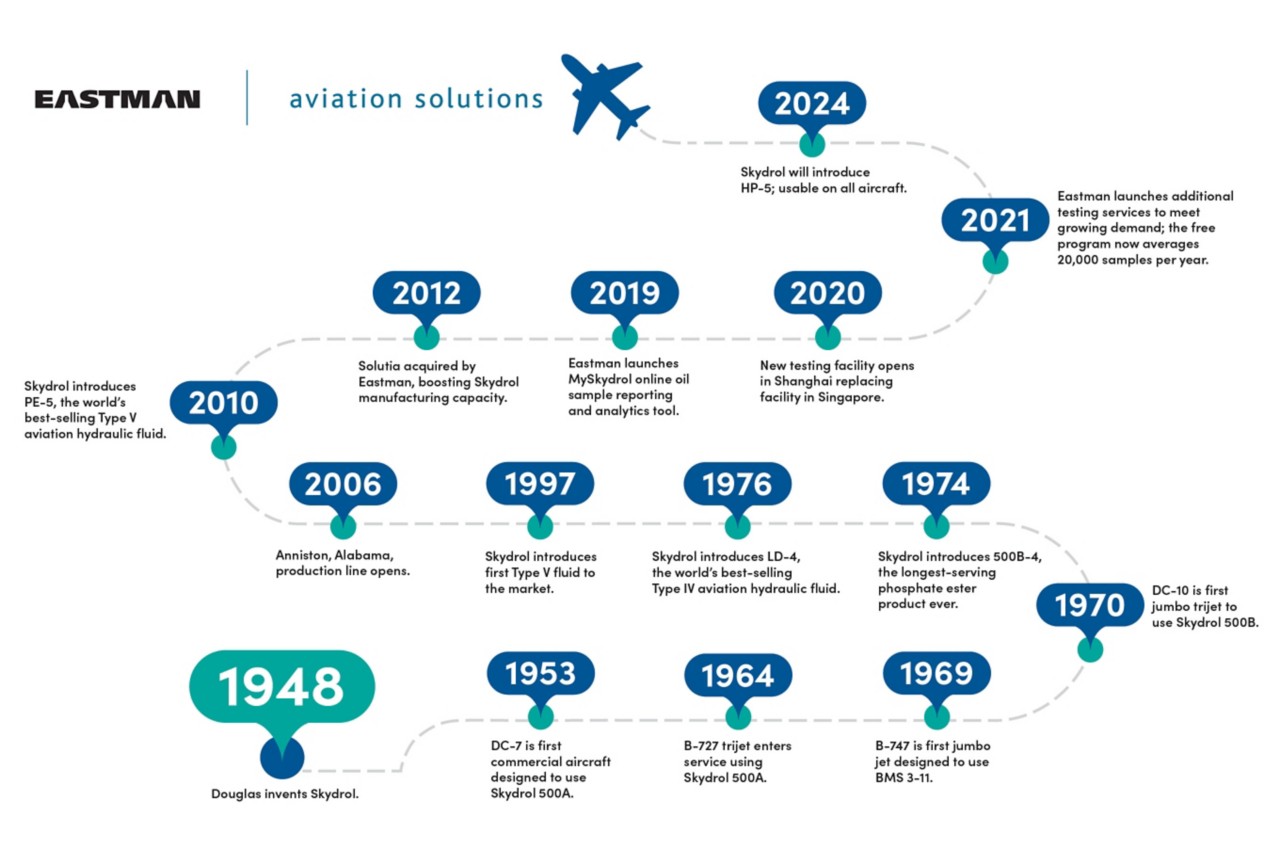

Hydraulic fluids let the pilot control the plane’s mechanical components by transferring power from part to part. This is done while offering lubrication and pump efficiency. Since 1948, Skydrol has helped planes manage turbulence, brake on the runway, and carry people around the world safely. The world’s air fleet has logged about 2 billion operating hours using Skydrol since 1964, and it remains an industry leader.

A storied history

Commercial aviation took off in the United States following World War II. Larger engines were built to accommodate bigger aircraft, so higher pressure was designed into hydraulic systems to manage resulting weight gains. According to John Churchill’s “Skydrol History, a Memoir,” flammable mineral oils used in these systems increased the risk of catastrophe in the case of an accident. For the industry to advance, a safer fluid was needed.

The Douglas Aircraft Co. found a solution in phosphate esters, which could withstand the pressure without the fire hazard. The company partnered with Monsanto Chemical Co. to develop the fluid. Within a decade, Skydrol was in use across North America and Europe.

In the following decades, fluid properties were improved to meet evolving industry needs, including improved erosion resistance, thermal stability and performance at lower density to reduce weight and fuel consumption. “Skydrol stayed relevant because it changed to meet the needs in the industry,” said Terry Wolfe, who spent 40 years as a chemist with Monsanto and its subsidiary Solutia, which branched off in 1997. “I think if no fluid like Skydrol was available, commercial aviation would have survived but wouldn’t be as efficient because we would need more safeguards on planes. A primary advantage of Skydrol is that it gave the designer more leeway so that the plane isn’t as heavy.”

Enduring legacy

Eastman’s acquisition of Solutia in 2012 boosted Skydrol’s manufacturing capacity and resource stability while incorporating what Christopher Alldredge, Eastman laboratory tech, called “the Eastman advantage.” Airlines can submit samples to make sure the fluid is still usable. Around 20,000 tests are done per year at sites in the United States, U.K. and China. Services include regional, customer-facing product and application support, state-of-the-art technical resources for consulting and advanced lab testing.

“It costs our customers money when their planes are on the ground,” Alldredge said. Routine fluid checks and accessible customer service can help prevent unscheduled aircraft maintenance. “Skydrol can last a very long time with proper maintenance,” said Michelle Spurlin, an Eastman site services and lab manager. “The reason we like our in-service programs is we stay in contact with our customers throughout the lifetime of the fluid.”

Always evolving

In the spirit of continued innovation, the latest version of Skydrol is completing a years-long testing process and is approved on all aircraft types, offering longer fluid life and requiring less maintenance, according to Ashley Mitchell, an Eastman research technician.

“Skydrol and the aviation industry have grown together,” Payne said. “We've met safety expectations for three quarters of a century, and our commitment to innovation will ensure we rise to the occasion for the next 75 years.