A better option

There is a growing focus on biopolymers and circular options for food packaging. Unfortunately, many biopolymers are challenging to process, require capital investment to existing lines and have inferior end-use performance.

Solus™ can alleviate these concerns by improving paper adhesion, enabling faster coating speeds. It also facilitates reduction in coat weight and lowers scrap rate compared to incumbent biopolymers alone while leveraging existing assets.

Beyond these performance advantages, Solus™ enhances sustainability from the start with its biobased content and recycled content1 via Eastman's carbon renewal technology. The use of biobased content enables recyclability of the product at the end of life. Paper coatings made with Solus™ are certified biodegradable and compostable,2 helping keep materials out of landfills.

1Recycled content using mass balance allocation

2TÜV Austria certified Solus™ as compostable in home and industrial uses.

Increase productivity

Our Solus™ solution offers 10%–15% higher output compared to PLA (per 1,000 cups).

Leave nothing behind

Articles made with Solus™ biodegrade in months, while LDPE can take decades.

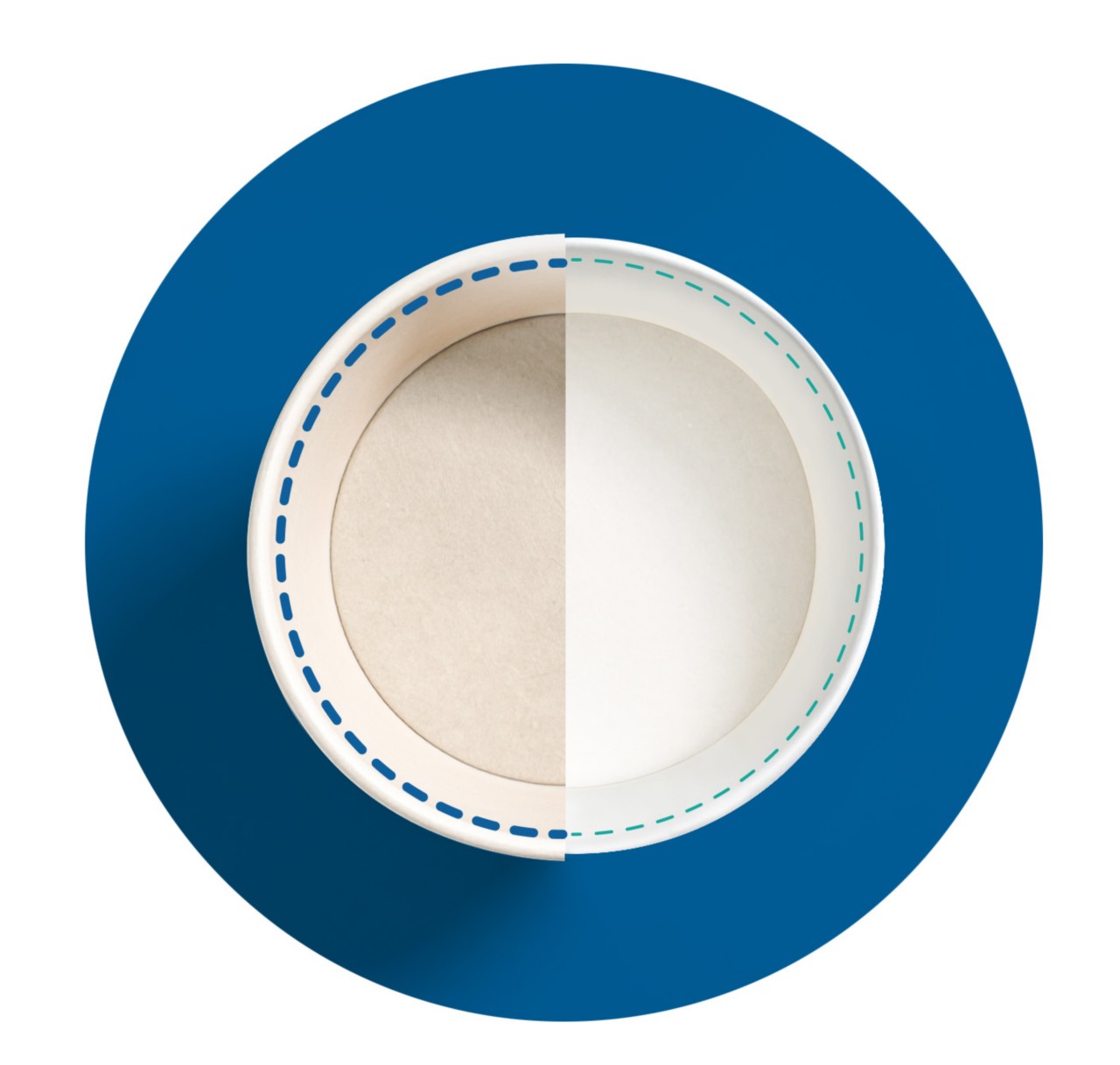

Downgauging

Enable coatings to be up to 50% thinner without compromising performance.

Testing and certifications

*Paper and Board — Recyclability Laboratory Test Method — Part I: Recycling mill with conventional process and evaluated acc. 4evergreen Fiber-Based Packaging Recyclability Evaluation Protocol, Version 1 (January 2025).

Be the change.

Elevate your brand and reduce waste. Eastman Solus™ gives brands, coaters and converters a competitive edge by simplifying processes and enabling high-performance, sustainable coatings that help reduce waste and environmental impact. Reach out to an Eastman representative to get started.